Every new generation of emergency products from Ektor have been painstakingly engineered to perfection in Australia. Boasting one of the biggest engineering teams in the industry, you can be confident that we have the expertise to meet your requirements. For several generations, our products have offered groundbreaking features such as: Out of the box self-testing, smart charging, full DALI compliance and certification. Generation IV continues to lift the bar in performance, reliability and safety with newer, smarter features.

Our class leading product ranges

The 4th Generation

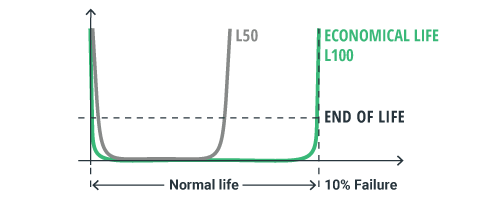

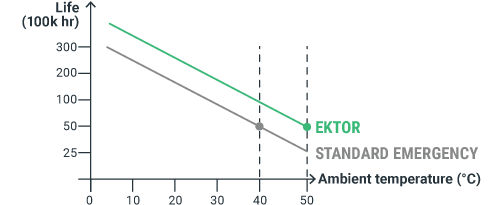

Taken to the next level, our 4th generation emergency product range sets a new standard. Generation IV delivers on three new key points:

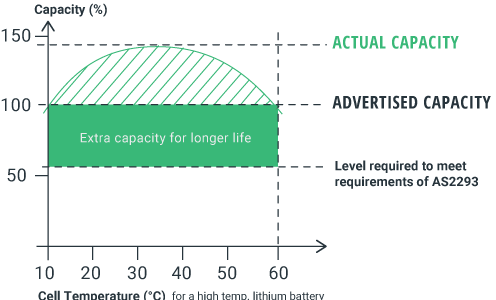

Designed for LiFePO4

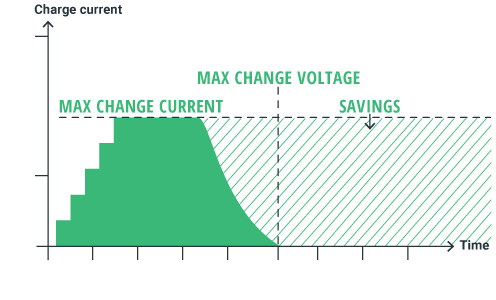

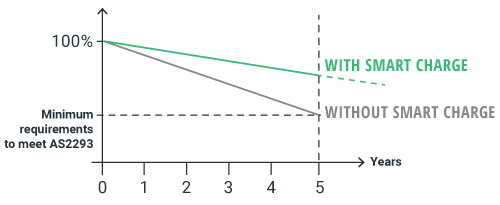

Smart charge, maximising charging efficiency

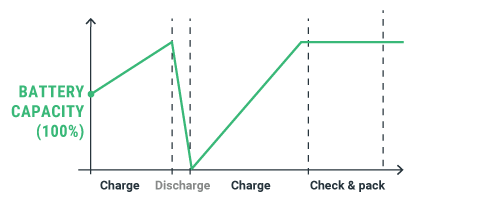

The New Generation of Ektor devices implement smart charging specifically designed for LiFePO4 batteries. It uses a new charging algorithm designed to maximise both energy efficiency and duration of charge. The system continuously monitors the battery to ensure it is always performing at its peak and is ready for the next emergency. Smart battery charging brings emergency lighting out of the dark – it helps to extend battery lifetimes, saving money while optimising performance.

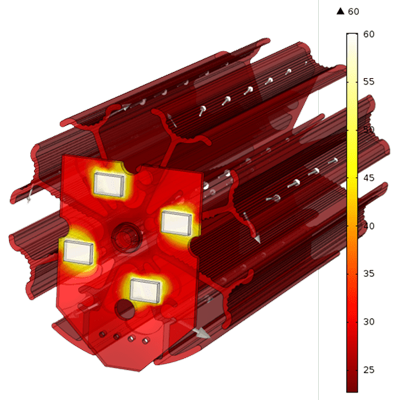

Quality Engineering

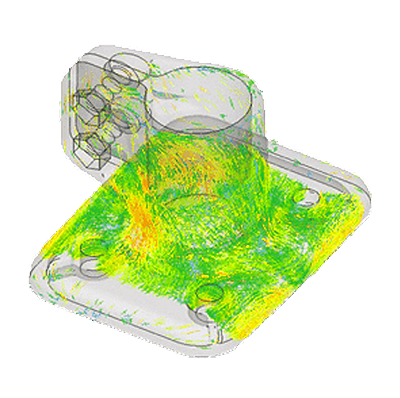

Engineered Quality for High Performance Products

The New Generation of Ektor products have been designed to be the best performing products on the market today. Providing the best value, best energy consumption, optimal output and quality design; no short cuts have been taken in ensuring that our customers receive nothing but the best.

Quality materials

Polycarbonate Plastic

High quality polycarbonate plastic is used in all our products removing ABS plastic from the mix. Polycarbonate provides a higher strength product and doesn’t produce the thick smoke that is normally produced by ABS and ABS + PC mixes when burnt. PC also provides better resistance to many chemicals found in specialised production facilities and farming sheds. For more information on the chemical resistance of the New Generation products see our Chemical resistance sheet.

Adhering to STANDARDS

Fully DALI compliant and certified

Our range is fully compliant and certified to not only DALI but also the new DALI-2 standard. Evolt, the manufacturer of Ektor, is dedicated to moving the lighting and control industry forward and that means investing in the ever-improving DALI lighting control standard.

“DALI-2 helps fill the gaps in the original standard, resulting in significant improvements in interoperability. DALI-2 adds new features, and introduces standardisation of control devices including the recent addition of input devices, while maintaining backwards compatibility “ – DiiA Digital Illumination Interface Alliance

Find your local distributor now